Sodium-Ion Batteries vs Lithium-Ion Batteries

Sodium-ion

batteries (NIBs) are an emerging alternative to traditional

lithium-ion

batteries (LIBs) currently used in most electric vehicles (EVs).

Reports indicate they have the potential to be safer and more

environmentally friendly as they do not contain toxic or

flammable

materials.

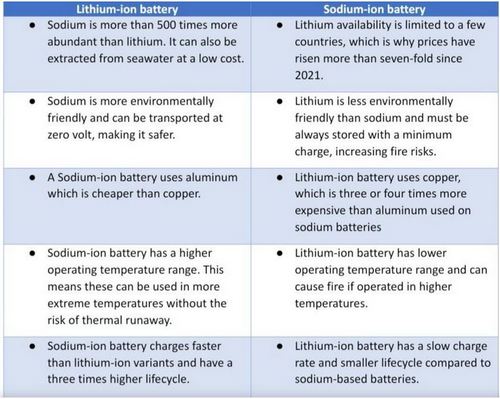

While LIBs are known for their high energy density and

relatively long

lifespan, they have several drawbacks. This includes high cost,

environmental concerns and limited availability of key materials

such

as cobalt, nickel, and manganese. In some NIB designs, copper as

a

current collector is

replaced by aluminum, a cheaper and more abundant metal (see graphic).

Sodium-ion

batteries (NIBs) are an emerging alternative to traditional

lithium-ion

batteries (LIBs) currently used in most electric vehicles (EVs).

Reports indicate they have the potential to be safer and more

environmentally friendly as they do not contain toxic or

flammable

materials.

While LIBs are known for their high energy density and

relatively long

lifespan, they have several drawbacks. This includes high cost,

environmental concerns and limited availability of key materials

such

as cobalt, nickel, and manganese. In some NIB designs, copper as

a

current collector is

replaced by aluminum, a cheaper and more abundant metal (see graphic).

Over the last few years, scientists at the Central South University in Changsa, China have been developing NIBs as an alternative to LIBs. Chinese battery maker Hina and Sehol -- a joint venture brand of Anhui Jianghuai Automobile Group Corp (JAC) and Volkswagen Anhui -- have together built a test vehicle with NIBs, based on the latter's Sehol E10X model. "The sodium-ion battery technology and performance could be used in mid-to large-sized EVs as it matures further," a Hina executive is quoted as saying.

According to JAC, its new EV is equipped with a 53.6 kilowatt hour (kWh) NIB pack that provides a range of up to 500 kilometres (km) on a single charge. The battery can be fast-charged to 80 per cent capacity in just one hour. JAC also highlighted that NIBs can operate under extreme weather conditions, from minus 40 degrees Celsius to plus 70 degrees Celsius. LIBs cannot do this, which is another one of their drawbacks.

In a recent article published in the New York Times, we read that "sodium, found all over the world as part of salt, sells for one to three per cent of the price of lithium and is chemically very similar. Recent breakthroughs mean that sodium batteries can now be recharged daily for years, chipping away at a key advantage of lithium batteries. The energy capacity of sodium batteries has also increased. And sodium batteries come with a big advantage: They keep almost all of their charge when temperatures fall far below freezing, something lithium batteries typically do not do."[1]

The ability to use sodium from salt is significant given that one of the major issues in the transition to electric vehicles and electrification in general is the cost of batteries and their functioning in harsh environments. If the global auto monopolies, especially, can reduce the cost of the batteries using public subsidies and salt rather than lithium, as well as cut back their work force significantly because electric vehicles require far less parts, they stand to make more profit.[2]

The world's largest manufacturer of electric car batteries is Chinese manufacturer CATL. It will soon be opening a base for the production of NIBs called Cheliwan Production Base in Ningde, central China. CATL is also very much involved in manufacturing rechargeable batteries for mass power storage in China. At this time the company has developed technology to pair LIB packs with NIBs in what it calls its AB battery pack. This battery pack has the ability to support EV ranges of up to 500 kilometres, said Huang Qisen, vice president of CATL Research Institute, at a November 2022 forum. With its AB battery system CATL has achieved a mix of the two types of electric batteries, allowing them to complement each other and thus increase the energy density of the battery system. NIBs are less energy dense than LIBs which essentially means more mass is required to get the same energy capacity and this increases the weight and space requirements. By mixing the two types of batteries, CATL is able to get the benefits of each type in one pack.

In two years, China will have nearly 95 per cent of the world's capacity to produce NIBs. Out of 20 NIB factories now planned or already under construction around the world, 16 are in China, the consulting firm Benchmark Minerals informs. Although LIB production will still dominate the rechargeable battery market at that point, advances in sodium are accelerating, Benchmark Minerals says. Companies in North America are trying to catch up.

In a May 4, 2022 press release, U.S.-based NIB designers Natron Energy and Clarios International, "a subsidiary of Brookfield Business Partners," announced that they are in a race to outdo Chinese giant manufacturer CATL. They are collaborating to set up what they called the "World's First Mass Manufacturing of Sodium-Ion Batteries."[3]

The Natron-Clarios NIB producing plant will be located at the Clarios Meadowbrook facility which already produces LIBs. The Natron-Clarios plant is in Holland, Michigan, U.S. Natron says that the similarity in manufacturing requirements allows the two companies to use part of Clarios' lithium-ion facility for sodium-ion production. This is expected to result in lower costs and faster time to market compared to building a new factory. The project to retool the existing plant is being financed by the U.S. Department of Energy's Advanced Research Projects Agency (ARPA-E) through the Seeding Critical Advances for Leading Energy Technologies With Untapped Potential Program (SCALEUP).

Map

showing location (highlighted in yellow) of Natron-Clarios

sodium-ion

battery plant in Holland, Michigan (left), the Ojibway salt mine

in

Windsor, Ontario (centre) and the Volkswagen battery plant in

St.Thomas, Ontario (right).

Map

showing location (highlighted in yellow) of Natron-Clarios

sodium-ion

battery plant in Holland, Michigan (left), the Ojibway salt mine

in

Windsor, Ontario (centre) and the Volkswagen battery plant in

St.Thomas, Ontario (right).

Notes

1. "Why China Could Dominate the Next Big Advance in Batteries," Keith Bradsher," New York Times, April 12, 2023.

2. Governments at All Levels Paying for Large-Scale Changes in Auto Industry, Enver Villamizar, Workers Forum, February 16, 2023.

3. In an article entitled "McGuinty Opens Space for Brookfield Vultures," in the March 6, 2012 issue of Ontario Political Forum, Jim Nugent had this to say about Brookfield:

"Brookfield is an aggressive international monopoly based in Toronto and New York. It is notorious amongst Canadian workers for its wrecking of productive enterprises, causing job losses and looting workers' pension plans. Brookfield was instrumental in wrecking Stelco and handing this national treasure over to U.S. Steel. It has specialized in shuttering paper mills and saw mills in the Maritimes, in Quebec and across the country to steal the power from the hydro plants connected to the mills and helping finance their big scores by looting pension plans of the workers they throw on the street.

"Now Brookfield is expanding rapidly into the Ontario public hydro sector to occupy the private sector space created by [Mike] Harris and [Dalton] McGuinty. Linking up with Hydro One on the EWT [East-West Tie] power distribution project will serve Brookfield's strategy of becoming a dominant global force in renewable power generation. A week before the bid for the EWT project was submitted, Brookfield consolidated all of its electricity holdings into one company, Brookfield Renewable Energy Partners, to prepare for competing in Canadian and global markets."

(With files from TML, New York Times, Brighter Side of News, CNEVPost, Benchmark Minerals, U.S. Department of Energy, Natron Energy, Clarios International. Photos: Unifor Local 240)

This article was published in

Number 25 - May 10, 2023

Article Link:

https://cpcml.ca/WF2023/Articles/WO10255.HTM

Website: www.cpcml.ca Email: editor@cpcml.ca